INFRA

We operate through 3 partially vertically integrated manufacturing facilities, namely:

(i) Automotive lighting OEM and aftermarket plant at Bahadurgarh, Haryana (“Unit 1”) which is dedicated for the manufacturing of automotive lighting products and components;

(ii) Sheet metal plant at Bahadurgarh, Haryana (“Unit 2”) which supports our lighting operations through sheet metal fabrication and precision stamping components and

(iii) Automotive lighting OEM plant at Pune, Maharashtra which recently commenced operations. (“Unit 3”) (“Manufacturing Facilities”).

Our Manufacturing Facilities are strategically located near key automotive OEM clusters in North and West India. This location advantage is a key strength, as it helps us provide enhanced flexibility, better inventory management, and a more personalized approach to meeting the unique needs of each customer. By being closer to our customers, we can build stronger relationships, ensure their satisfaction and fostering long-term partnerships. According to CRISIL Report, our Manufacturing Facilities are strategically located near key automotive OEM clusters in North and West India, and with a new facility planned in Kancheepuram, Tamil Nadu, we expect to have a manufacturing footprint across major automotive corridors in the country.

Manufacturing

Environmental Control

The whole plant is divided into pressurized and non-pressurized zones with single point entry systems. These zones are backed by a set of HVAC Utility Equipments:.

– US make York Air Cooled Chillers – 750 TR

– Zeco make AHUs – 10 AHUs

– Denmark make VFDs in each AHUs.

Assembly Line

Highly flexible, dedicated semi-automatic assembly lines are installed as per customer requirements.

Assembly shop is located between Surface treatment, BOP store and FG store for minimal material movement. Assembly lines are also equipped with vibration welding machines.

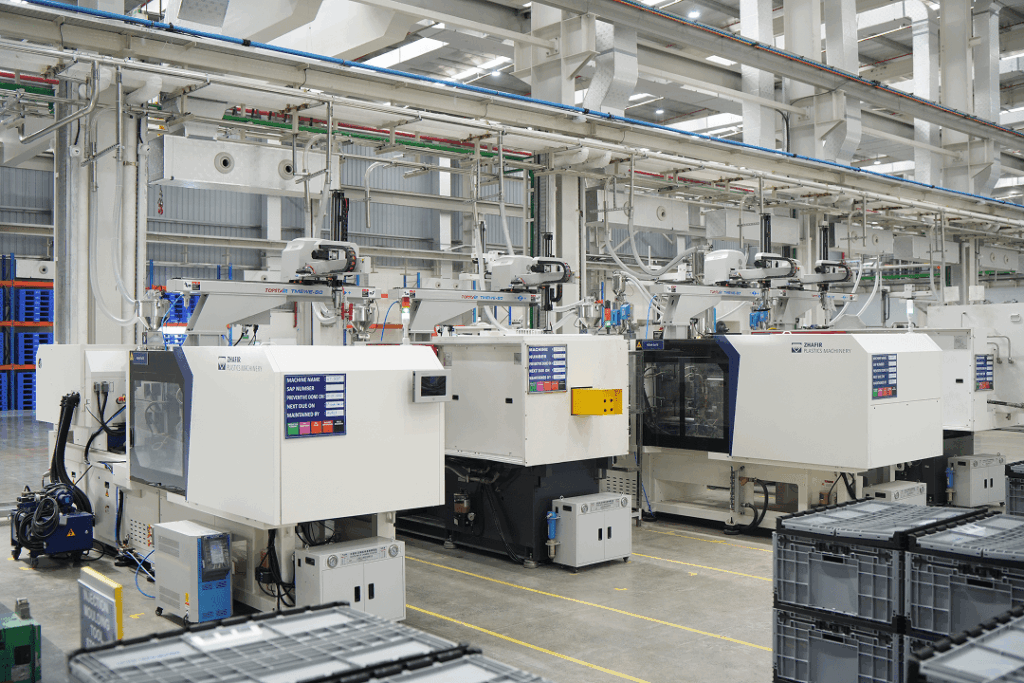

Plastic Moulding

Fully Robotic Plastic Injection Moulding Shop (Including Thermoplastic & Thermoset)

The Moulding Shop is equipped with 37 Nos moulding machines (including Multicolour Moulding) ranging from 80 Ton to 1360 Ton. It also includes 9 Nos All Electric moulding machines.

Base Coating Plant

Automated Vertical storage system for the storage of materials connected with SAP

SMT Line (Surface Mount Technology)

NEOLITE ZKW has installed In-house SMT lines which enables to manufacture the latest, sophisticated, and complex LED designed lamps with competitive price, highest quality, faster delivery time, leading to customer satisfaction.

Integrated Hard Coating

UV cured, Robotic spray Hard coating Plant in Clean Room environment (10,000 Class) for PC Lenses.

The Hard coat line is integrated with annealing oven and injection molding for online feeding of lens.

Tool Room

We have the capability to build complex Toolings / Moulds inhouse and have requisite Infrastructure and Experienced personnel. Our Tool Room is equipped with most modern equipment’s to develop any product from concept to production. The manufacturing Set-up duly integrates with a large tool room, backed by latest software’s and CNC machining facilities.

Antifog Coating

Fully Integrated Antifog Coating machine Connected with Hard Coating with a coating substrate length of 1600mm in one go in 10,000 Class Cleanroom.

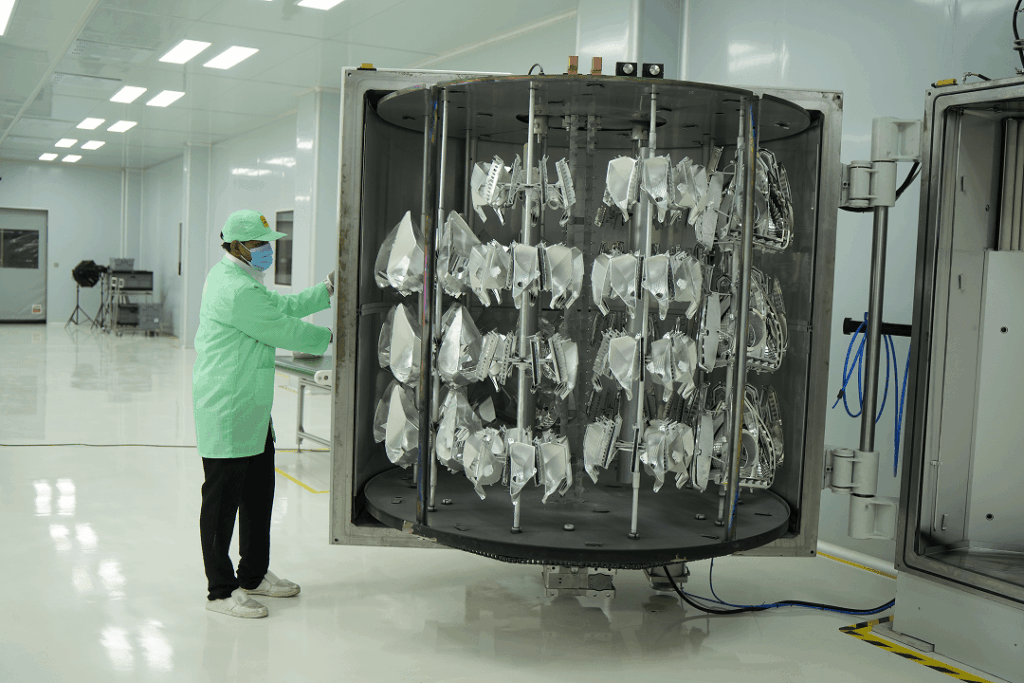

Vacuum Metalizing

Vacuum Metalizing machine with inbuilt top coat inside 10,000 Class Cleanroom.

Autonomous Mobile robots

Automated material movement inside the shop floor using AMR.

Automated High rack Storage

Fully Robotic Plastic Injection Moulding Shop (Including Thermoplastic & Thermoset)

The Moulding Shop is equipped with 37 Nos moulding machines (including Multicolour Moulding) ranging from 80 Ton to 1360 Ton. It also includes 9 Nos All Electric moulding machines.

Laboratory

Our next-generation lighting test facilities are equipped with advanced instruments and fully automated setups to ensure accurate and reliable validation of automotive lamps.

Environmental Control

The whole plant is divided into pressurized and non-pressurized zones with single point entry systems. These zones are backed by a set of HVAC Utility Equipments:

– US make York Air Cooled Chillers – 750 TR

– Zeco make AHUs – 10 AHUs

– Denmark make VFDs in each AHUs.

Assembly Line

Highly flexible, dedicated semi-automatic assembly lines are installed as per customer requirements.

Assembly shop is located between Surface treatment, BOP store and FG store for minimal material movement.

Plastic Moulding

Fully equipped Plastic Injection Molding Shop (Including Thermo & Thermoset plastic).

The moulding shop is equipped with 22 Nos moulding machines, ranging from 80 Ton to 1300 Ton. It also includes one all electric and one Engel make multi color Injection machine.

Base Coating Plant

UV Cured, Robotic Spray Basecoat plant in Clean Room environment (10,000 Class) for BMC Reflectors without manual intervention. Line is placed between Plastic Molding and Vacuum coating plant for single line material flow.

SMT Line (Surface Mount Technology)

Integrated Hard Coating

UV cured, Robotic spray Hard coating Plant in Clean Room environment (10,000 Class) for PC Lenses.

The Hard coat line is integrated with annealing oven and injection molding for online feeding of lens.

Learning Centre

We have created a real time learning centre on shop floor where all the production associates will be trained for their role.

Tool Room

We have the capability to build complex Toolings / Moulds inhouse and have requisite Infrastructure and Experienced personnel. Our Tool Room is equipped with most modern equipment’s to develop any product from concept to production. The manufacturing Set-up duly integrates with a large tool room, backed by latest software’s and CNC machining facilities.

Laboratories and Equipments

Environment Chamber

Salt Spray Test Machine

Water Spray Chamber

LED Testing Lab

Hot Chamber

Cold Chamber

Dust Chamber

Profile Projector

CMM

Photo Goniometer

Spectrameter